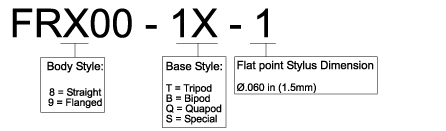

Testing & Measuring l Trulok Gages l Flushness Gages l FR900-1X11

|

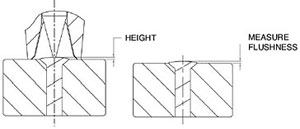

The FR900 gage provides a quick and accurate flushness measurement. The Ø .060 inch (1.5 mm) flat point stylus is perfect for measuring selected areas of the fastener head for flushness. The base is fixed and it has an internal ID of Ø .63 inch (16 mm). Used in combination with a countersink depth or a diameter gage provides the user with greater control of the fastener installation process. This versatile gage can check flushness for fasteners, welds and grooves. |

|||

Features: |

||||

|

||||

|